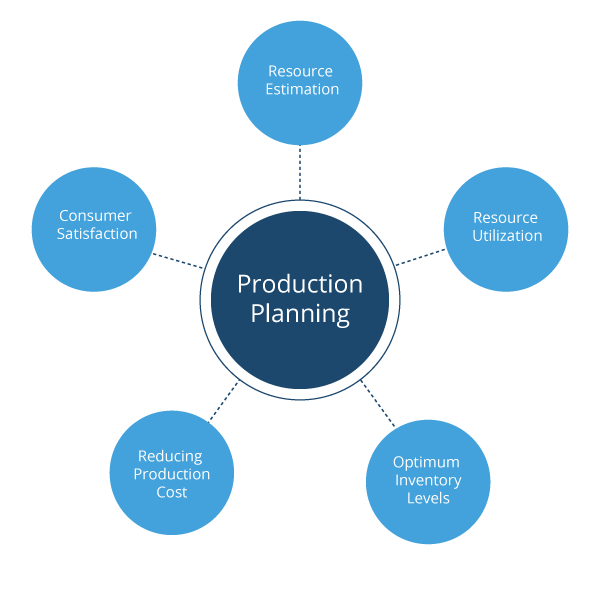

We all know that Production Planning is all about managing and allocating resources, materials, and capacities to ensure that consumer demand is served. But with ever-rising and rapidly changing technologies, the expectation from this process is bound to increase. This blog discusses the top 5 expectations from this process and also throws light on the significance of each one of them.

1. Resource Estimation

Production Planning models help to understand the required resources to ensure that the target output is achieved. The derived result also helps correct arrangements & allocations of resources

2. Resource Utilization

Effectively using most of the resources available to meet the objective. The process also allows understanding strategically measuring the efficiency of the resources.

3. Optimum Inventory Levels

Good stress on this aspect is observed in any and every organization. The right approach will ensure that the inventories are managed at the desired level

4. Reducing Production Cost

The sum of all the costs and expenses went into making a product determine the Cost of Production of that product. Production Control steps monitor the total production cost. A good Production Planning process will also target to keep the cost as low as possible without compromising on the quality of the output

5. Consumer Satisfaction

Any schedule that runs production should give the right output that matches consumer demand. Though there is always a possibility of defects and rejections in every run, with the right connection between consumer demand (Forecast), Material Requirement Planning (MRP) & Production Planning Control, the result will have an improved level of Customer Satisfaction

As a Planner from Production cell, did you ever get into a situation where resource and capacity allocation was always a challenge or looked difficult to achieve quickly?

Such challenges occur due to a lack of process and data visibility. Using ValQ, Modern Visual Planning for Microsoft Power BI, we can bring in more visibility and add a lot more value to our Production Planning Process.

Stay tuned for our next blog which will focus more on optimizing resources vs.capacities and the use of ValQ on running a successful planning process that supports Production.

To learn more, tune in to one of our ValQ Webinars or try our product for free here.