Think of how the interactions with various systems & computer applications have changed over the last couple of decades. Across websites, search engines, mobile devices, video content, mobile applications, games, visualization software and social media – an underlying revolution has been happening quietly, in terms of user experience & design.

Now let’s look at planning systems and processes, and we’ll take for example – “Material Requirement Planning”. Though the systems have evolved over the last few decades in terms of technology & features, the usability of these systems have not improved much. So much so that many organizations still rely on spreadsheets – which are quicker, but suffer from challenges such as collaboration, security, data quality & isolation. For various reasons including this, Material Requirement Planning (MRP) still continues to stress manufacturers who expect a better and responsive – and perhaps even proactive – supply chain system.

However, this need not be impossible to achieve for enterprises.

Visual Material Requirement Planning with ValQ

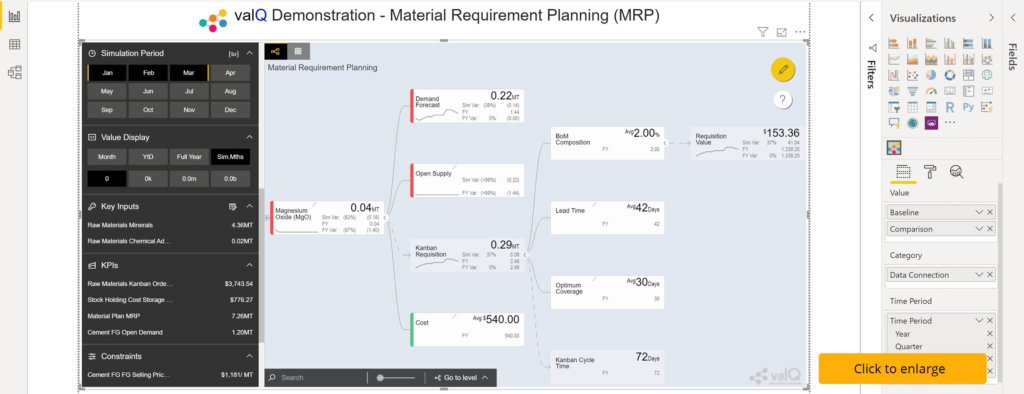

With ValQ, Modern Visual Planning for Microsoft Power BI, users get a ‘visual’ material requirements plan that delivers excellent user experience. It also allows users to run several scenarios ‘intuitively’ and ‘quickly’ for making faster decisions. Unlike spreadsheets, the visual nature of ValQ ensures that your MRP and its dependencies are easily understood by executives, managers, analysts & planning professionals. It even allows you to easily compare scenarios and generate reports such as variance analysis, something that is not easy to do with excel spreadsheets.

Take a look at the snapshot from ValQ for Material Requirement Planning – when was the last time you came across a MRP solution that was as visual or engaging?

The result – your users get a business-driven, user-centric, self-service capability at a minimal cost – that they can embrace to drive material requirement planning.

With ValQ, you can model your MRP along with key drivers such as Demand Forecast, Open Orders, Inventory (raw material & finished goods), Bill of Material (BoM) components, Optimum Coverage and Vendor Lead Times – to build a comprehensive material requirement plan – ‘quickly’.

Let us change the way we do planning because only ‘Change‘ is constant. This reminds me of Carol Burnett who had once said ‘Only I can change my life. No one can do it for me’.

In the subsequent blog, let’s learn the differences between a traditional MRP solution vs. ValQ, with the latter being modern and visual solution.

To learn how ValQ can help you drive on-the-fly material requirements planning, reach out to us here today.